Thought I should upload some pickies of what keeping me off the streets at the moment.

Although, the aim is to keep me ON the streets when it's finished.

I have been hunting for a panel van for a few years, thought it could be handy, and when I got a windfall in pay due to being underpaid for almost a year, I decided to throw some money into a Brougham project that i have had here for some time.

As luck would have it I came across A van on eBay not too far away and went to have a look. I had wanted a HK-G series, as I have heaps of parts collected over 30 years.... Glad I did take that look......

This is just some of the problems, but everything was like this.

Then a "99% rust free" one came up (his words),

bare shell, but close by and the price was right, cheaper than the first.

Well it followed me home

Getting it into the shed

On some crude skates to move around the shed

It was all class.... Sweet velour roof lining and matching red seatbelts, about the only thing on the shell besides the body wiring.

But it did come with a driver......

Albeit a little deceased.

I have the skull and the forearms (look like King Julian's sceptre) and I'll use them as toggle switches and an air cleaner hold down wingnut. Jeeez I'm classy.

NO rust inside the cabin and tray area..

But this was the 4 speed conversion

So there will be a replacement welded in to clean this up. As it will be using the powertrain from a Brougham, the glide won't need the hole in the floor.

This is the sorry donor for the drivetrain, windows, doors, front panels and glass

It was too much work to fix the substandard repairs on this one in a shortish time frame. This is some of the "work" done on it.

I'll get to this later, as I don't want to wreck a model in such short numbers.

Previous repairs on the van were welded with reasonable skill, but some of the fitting and patch panel making required lots of bog i am starting to find.

This is a floor repair.

The outside of the sub frame near the steering box. The finish wasn't flush, but it was well protected, and the inside was seamless. I'll finish this one off and leave it.

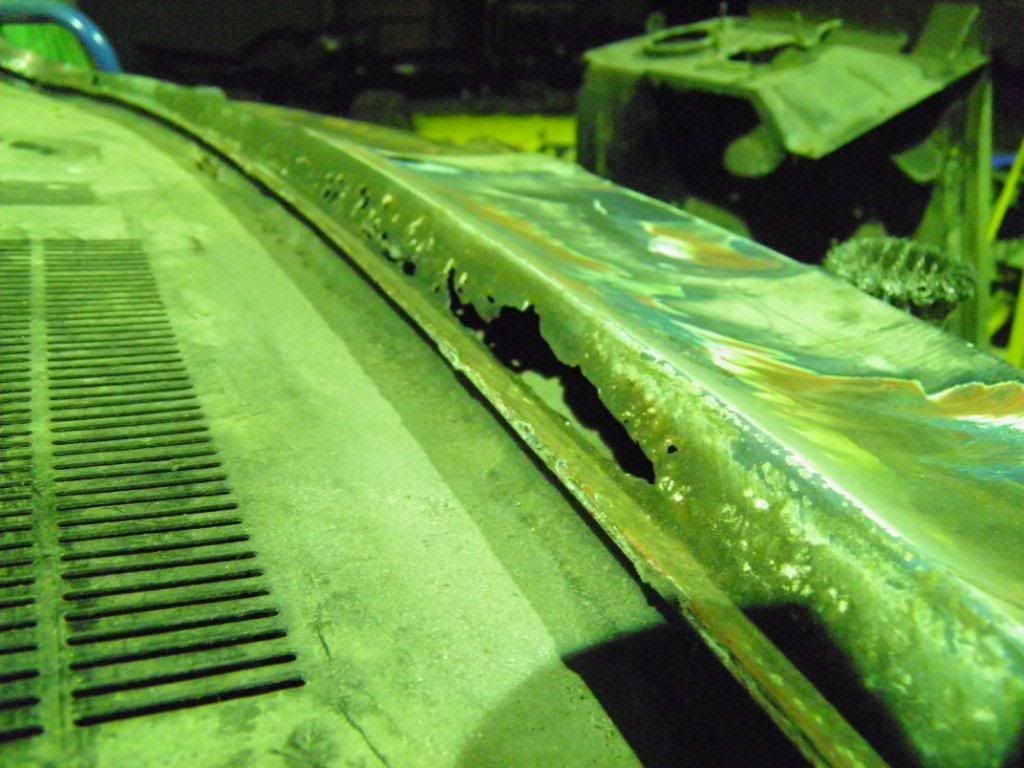

Look what I found when i tickled the frame with a wire brush....WHY cover it with bog, when the upper part of the frame had an excellent welded repair???

Well... there

was no rust.... just no metal too!!

This was welded ok, but just didn't fit the profile of the panel

I'll make a new one and cut it out.

A cut and shut repair from something earlier. Tidy up needed, but I'll do that when the frame is back on the body.

BIBI panel beating....bash in and bog it

Getting a new quarter section for this repair... too far gone. (Well it looked straight in the first inspection, and FAR better than the first one i looked at)

Stripping it down

Going to put a sedan rear bumper on it(with a lot of fiddle)

There is absolutely no rust in the sub frame mounting areas, as well as the mounting legs.... unheard of..

They all look like this!!

Edited by user Sunday, 8 May 2011 7:11:47 AM(UTC)

| Reason: Not specified